Seaming Stone and Quartz with Surface Bonder Xi and Surface Bonder Zero

Seam Preparation

1After cutting, the surface needs to be cleaned of dust/sludge that accumulates on the edges. The bulk of this can be washed away with water (either use water under pressure, or use your hand to ensure that dust is lifted). It is recommended to use acetone or alcohol for a final white to ensure the surface is contaminate free.

2Before applying adhesive, ensure that the surface is dry. Porous surfaces (granite, marble, limestone, etc.) need extra attention to make sure moisture has evaporated.

3The surface and adhesive should both be at room temperature.

4Apply masking tape on each side of the seam, back about 1/16 inch from the joint. (Build up 2 to 3 layers of tape).

Application

1 Place cartridge in dispenser. With the cap removed, purge adhesive until you can see both components are present and flowing. Usually both should be visible after one trigger pull.

2 Attach a mixing tip and purge until the mixing tip is saturated with adhesive. Purge one full trigger press of adhesive into a cup or other receptacle to ensure that components are mixing thoroughly.

3 Apply a bead of adhesive to the surfaces to be bonded. While you may prefer to run a single heavy bead on one surface, we recommend two lighter beads on each. This ensures wetting of both edges. *Be mindful of the amount of force used on the dispensing gun. Adhesive should flow with relative ease. Excessive pressure can disrupt mix ratio.

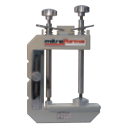

4 Clamp your surfaces together. This will vary depending on what you’re seaming (for deck seams Gorilla Grips, for laminations Spring Clamps, and for mitred edges MitreForma™ Clamps). Don’t over-tighten clamps.

5 To reduce labour, wipe adhesive flat with a putty knife using the masking tape as a gauge to leave a little overflowed adhesive on the seam. Wipe in both directions to fill any chips and gaps. Remove the tape as soon as possible. After ~3 minutes the adhesive will start to skin over which will make removing tape more difficult.

6 The open time for the adhesive is approximately 12 minutes at normal room temperature. After the bead is fully cured (approximately 25-30 minutes) it can be scraped flush with a razor blade. The adhesive will shrink as it cures, so make sure adhesive is fully cured before scraping or it will continue to shrink into the seam. To test, press the blade into the bead and look for denting/marking from the blade. Some areas may cure faster or slower than others, so test a few areas across the seam.

7 For polished surfaces, polish the joint with your preferred polishing compound to enhance the lustre and color.

Color Matching

Integra is known industry wide for its excellence in matching colors. The lab uses a combination of technical equipment and experience to produce unrivalled color matches for every surface. Color match charts are updated regularly with new matches for new sheets from manufacturers. While most surfaces can be matched using the top 20-30 adhesive colors, Integra customers have access to a palette of over 300 colours, and our lab can produce any colour under the sun should the need arise.

Storage and handling:

Methacrylate Adhesives and Activators are flammable and can be dangerous if used improperly. Avoid skin and eye contact. In case of eye contact flush with water for 15 minutes and get medical attention. Keep away from sources of ignition. Before use or handling, consult the appropriate Material Safety Data Sheet (NA,EU). Information is supplied at time of initial purchase and may be requested from the manufacturer or downloaded from the product page. Store the adhesive in a cool area away from direct sunlight. High temperatures will reduce the shelf life of the adhesive and activator. Exposure of activators, including cartridges, which contain activators, above 100°F. rapidly diminishes the product’s reactivity and must be avoided. Refrigeration is an acceptable means to increase storage life, however freezing should be prevented. Shelf life results are based on constant temperature storage between 55–75°F (12–23°C).

Dispensing / Packaging

Surface Bonder Xi is packaged in dual component cartridges as part of a meter/mix/dispense system utilising specialised dispensing guns and static mixing tips. Surface Bonder Xi is available in 100ml, 250ml and 500ml cartridges.

Surface Bonder Zero is currently available in the 250ml cartridge with an expanding base range of 45 colors.

Shipping Options

Integra’s adhesives are stocked at multiple locations across North America and Europe. A 1 — 2 day lead time can generally be expected for ground delivery within the continental US and Canada.